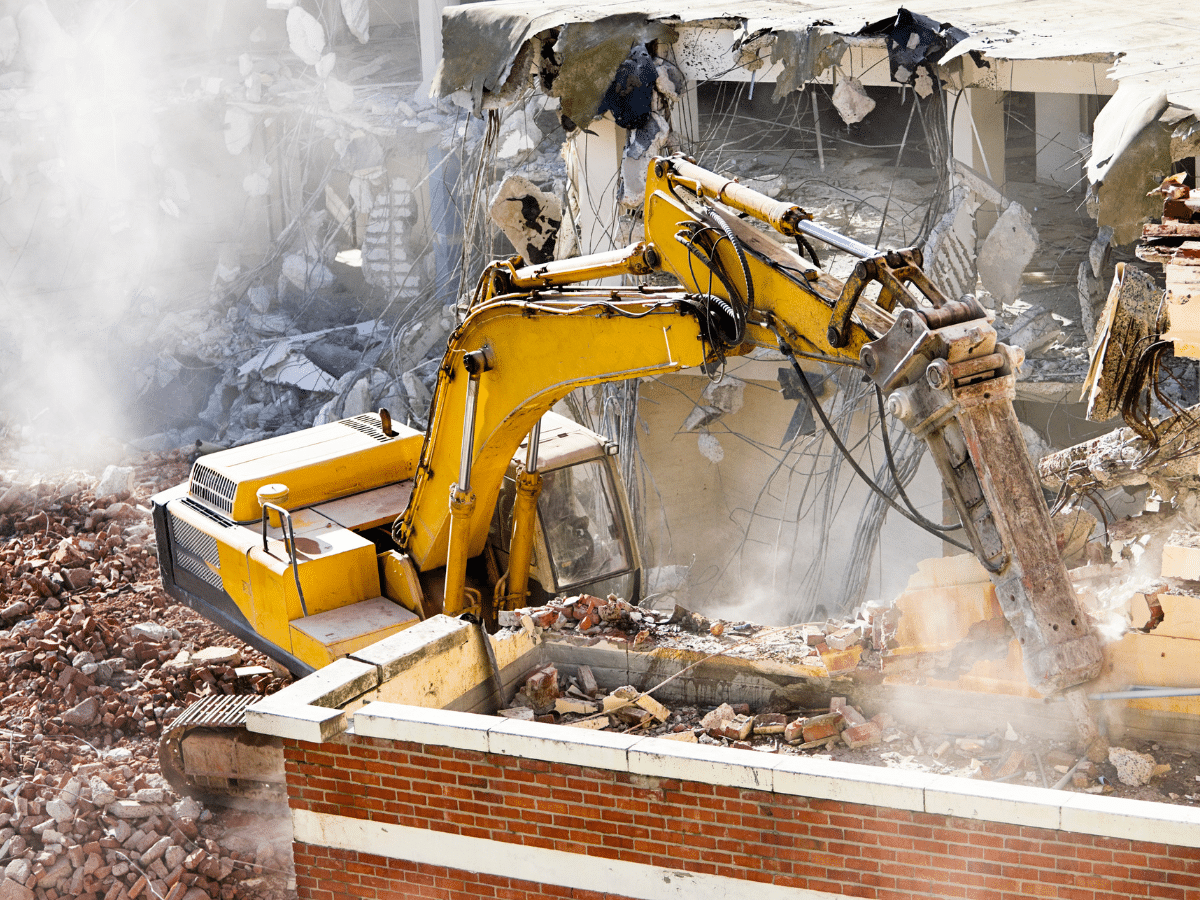

Demolition is the process of tearing down or destroying structures. It can be done for various reasons, including clearing the way for new construction or removing dangerous or abandoned buildings.

Demolition is a complicated process that requires careful planning and specialized equipment. When choosing a demolition company, choosing one with experience and a strong safety record is important. Contact Diversified Management & Construction, Inc. now!

Demolition is a hazardous job, but workers can reduce the risk of injury by taking certain safety precautions. These include using protective equipment, following the proper demolition methods and protocols, and avoiding exposure to dangerous chemicals. Workers should also familiarize themselves with the specific regulations that apply to the specific project, as these may vary by state or by structure type.

Before any work begins, a thorough survey should be conducted on the site. This will help identify potential hazards, such as unstable structures or buried electrical and gas lines. The survey should also include an evaluation of the condition of the structure to determine if it needs to be braced or shored before demolition work can begin. Likewise, the survey should determine whether the structure has any unplanned openings that could expose workers to flying debris.

Once the survey has been completed, workers can safely start to dismantle the structure. This should be done in stages, starting from the top and working down. Workers should wear appropriate protective gear and disconnect all utilities as they proceed. If necessary, they should also use hand tools to break up concrete and remove non-structural components. Once these steps have been taken, they should carefully dispose of all debris and salvage materials.

During the demolition process, it is essential to follow all local and federal regulations. Workers should also have an understanding of the demolition equipment they are using, including how to properly operate and maintain it. In addition, all workers should be trained on the specific hazards that they will encounter and the safety procedures that they should follow to avoid injuries.

Some of the most common safety hazards in demolition include vibrations, dust, and noise. These can cause serious harm to workers and members of the public. To mitigate these risks, employers should ensure that all employees are adequately protected by wearing appropriate PPE and that they have access to regular training. In addition, they should implement engineering controls (such as constructing barriers or redesigning equipment) and administrative controls (such as creating work schedules that do not result in excessive exposure) to reduce these risks.

Preparation

When a property is slated for demolition, there are a number of different processes that need to be completed. This process includes surveying and inspecting the structure to identify any potential safety hazards, obtaining the necessary permits, disconnection of utilities, and establishing clear communication with the community.

In some cases, a structure may need to be stabilized prior to demolition. This can involve reinforcing or shoring to prevent structural collapse during the demolition process. It also involves removing non-load-bearing walls and drywall to facilitate the demolition process. It is important that these steps are taken to avoid costly damages caused by the demolition process.

Other preparation steps include preparing the work site and protecting the surrounding area. This typically includes erecting barriers and fencing, providing workers with protective gear, and conducting safety briefings. It is also crucial to monitor the site continuously throughout the demolition process to ensure that all safety protocols are followed.

It is also important to remove all hazardous materials from the site before demolition begins. This can include removing asbestos and lead paint, as well as cleaning up any other materials that could pose harm to people or wildlife. It is best to have a professional contractor perform this step, as it can be dangerous for someone to attempt on their own.

Another important step in the preparation process is to disconnect any water, gas, and electric lines that are connected to the structure. This will help to minimize the risk of fire, injury, or damage to nearby properties during the demolition. It is also important to have a full-time safety oversight personnel on site to make sure that all workers are following the proper procedures. This person can also host toolbox talks, offer one-on-one consultation, and keep track of incident reports.

The cost of the demolition process can vary widely depending on the size and complexity of the building. Some common costs are permit fees, equipment rental or purchase, labor, and waste disposal. Other expenses may include resale of salvageable items, signage, and site fencing. It is important to budget for all of these expenses before starting the project.

Equipment

Demolition requires special tools to ensure a safe and efficient process. From hand tools like sledgehammers to heavy machinery such as bulldozers and excavators, the right equipment can make or break your project. The type of equipment you use will depend on the size of your demolition site and the materials you’re taking down. The size of the machine and its attachments can also influence the speed at which you can work, allowing you to meet deadlines and save money.

For small demolition projects, you can use wheel loaders or skid steers to lift and transport debris. These machines are designed with a front bucket that easily scoops building materials and other debris into its body. They can then move the material to a truck or off-site location to be recycled or reused. You can also use these machines to break up larger structures using demolition attachments like shears or hydraulic breakers.

If your demolition project involves large buildings, you’ll need heavy equipment like backhoe loaders or crawler loaders. These heavy machinery are designed with metal tracks to drive over rough terrain and can move massive dirt piles during the demolition process. They can even be used to push down a building and clear out narrower areas of the site.

You may also need high-reaching equipment for certain types of demolition. Whether you’re tearing down a skyscraper or just remodeling a room, specialized tools can help you reach hard-to-reach places and save time. These tools can also be a safety concern if they’re not properly maintained and operated by trained professionals.

For small demolition jobs, you can use handheld tools like jackhammers to break down walls and other structural elements. These tools can be difficult to control, so it’s important to have a plan and stick with it. You can also use pneumatic demolition tools that use compressed air to break apart materials. These tools are less expensive than other options and don’t require a lot of maintenance. However, they’re still not as effective as larger pieces of equipment.

Communication

Demolition is a high-risk environment that exposes workers to hazards such as falling debris, power lines and unstable structures. Keeping workers informed and alert can help them avoid these hazards. Regular communication with staff is also important, as is providing training on personal protective equipment (PPE) and safe work procedures.

Before demolition starts, it’s vital to complete a survey of the structure to ensure its condition is sound. This survey should include checking for and locating underground services, such as water mains, and disconnecting them where possible. Likewise, it’s critical to perform a final sweep of the building and double-check that there are no people still inside or any items that shouldn’t be there.

Workers may encounter materials that require specialised handling or disposal, such as asbestos or lead-based paint. This will require training on how to identify and handle these materials, as well as proper disposal techniques. In addition, working with older buildings or structures can present additional risks due to structural instability or historical elements.

Communication can be a challenge on construction and excavation sites, as they often have multiple stakeholders, including subcontractors, suppliers and local authorities. Miscommunication can result in delays, accidents and expensive mistakes. Using technology, such as Storm’s push-to-talk solution, can improve communications on construction sites, reducing downtime and increasing productivity.

Safety measures should be implemented on a demolition project, such as using wetting agents to mitigate dust, and creating noise barriers around the site. Keeping dust levels below permissible limits can prevent respiratory problems and dirty working conditions for workers. It’s also crucial to monitor and measure noise and dust levels regularly, so that adjustments can be made if they begin to become problematic.

Workers should be informed of the presence of prestressed concrete members within a structure and instructed on how to safely operate machinery in these areas. They should also be aware that if they deviate from the prescribed procedures, they will be exposed to significant hazards and could put themselves or others at risk. In addition, workers should be trained in the correct use, fitting, inspection and maintenance of PPE and in the general principles of good plant and tool operation.